LEARN MORE ABOUT

HVS -WQM System

Proactive Water Management of Cooling Towers with Real-Time Water Quality Monitoring and Graphical Trending

HVS‐WQM System ‐ Water Quality Monitoring System

Our Product Development History

HVS Engineering Pte Ltd. was incorporated in 2005 to provide green and sustainable energy and water savings solutions for chillers and cooling tower applications. It obtained the status of SEEDS Enterprise (administered by the EDB-Economic Development Board) in October 2005 for the development of a novel automatic cleaning invention for tube and shell heat exchangers and sustainable water savings technology.

HVS Engineering Pte Ltd is a pioneering company working on an automatic online tube cleansing system with spiky balls of varying densities to ensure all tubes are being cleansed. The cleaning principle behind the patented HVS cleaning system is to create a dynamic zig‐zag mechanical cleaning process through specially designed off-centred spiky balls to clean the grooves of heat exchanger tubes by capitalising on the force of moving water through the tubes.

In 2013, HVS Engineering Pte Ltd developed a chemical-free water treatment system with A-Star IMRE and has been certified by the Singapore Green Building Council with SGBC 4 ticks since 2019 under the category Cooling Tower Water Treatment—Physical Devices (HVS-ECA System – Chemical-Free Water Treatment) which is suitable for open loop and closed loop water distribution systems. HVS has maintained constant efforts to improve our product efficacy and aspires to realise the benefits of sustainable water savings through smart technology.

In 2016, HVS Engineering Pte Ltd embarked on the development of a HVS-RBQ System (Rapid Bacteria Quantification System) with A-Star IMRE for the development of a rapid test kit for TBQ (Total Bacteria Quantification) and TLD (Total Legionella Detection). Extensive lab-based optimization and site validation on the bacterial load in cooling tower waters have been conducted over the past years. HVS has successfully developed Total Bacteria Quantification (TBQ) with a result outcome in 10 minutes. This TBQ testing protocol serves as a rapid tool to monitor the trend of the bacterial load over time and can be used as an early warning signal if a sudden upsurge of bacterial infestation occurs.

Currently, we are seeking further research collaboration with \ SIT (Singapore Institute of Technology) and NTU (Nanyang Technological University) to develop a rapid detection kit for legionella in cooling tower water that can yield a “YES or NO” and semi-quantification result outcome within 10 minutes. This rapid legionella qualitative “YES or NO” legionella test is meant to be a quick water quality test in Singapore on the water quality basin samples before being sent to an accredited lab for the standard culture plate test (HPC) and Legionella for validation. The accredited lab tests of HPC and Legionella will serve as official test reports to be submitted to the NEA as required by law.

In 2018, HVS Engineering Pte Ltd completed a HVS-WQM System (Water Quality Management System) — a cloud-based water quality monitoring and trending system specifically for open loop and close loop, to track water parameters like pH, TDS, ORP, free chlorine, total hardness, corrosion for SS (Stainless Steel), and corrosion for Cu (Copper) using LPR Technology (Linear Polarisation Resistant Protocol).

Our Energy and Water-Saving Solutions

HVS Engineering provides cost-effective energy and water-saving solutions for heat exchanger systems and cooling towers. We offer an improved automated method of cleaning and maintaining fluid-cooled tubes and shell heat exchanger systems which utilises design-specific resilient brush balls circulating within part of the heat exchange system to clean fouling at the initial stage of formation. It is able to continuously circulate the brush balls through the tubes as compared to the intermittent cleaning sequence of the old system. This is to ensure fouling would not have any chance to occur. These specially designed spiky/brush balls can also reach and clean the grooves of the tube, which are inaccessible to larger sponge balls. HVS Brush Balls’ unique property results in more effective cleaning and is reflected in savings of at least 10 to 18% in electricity bills.

HVS Engineering provides an effective chemical-free water treatment system that has been vigorously reviewed and certified by the Singapore Green Building Council with SGBC 4 ticks (LEADER) under the category Cooling Tower Water Quality Treatment—Physical Devices which is suitable for open loop and closed loop water distribution systems. HVS has maintained constant efforts to improve our product efficacy and aspires to realise the benefits of sustainable water savings through smart technology. Water savings between 15 to 20% have been validated in our past projects.

HVS-ECA System is essentially electro-chemical activation – utilising electricity to activate the production of oxidising chemicals for managing the water quality of cooling towers. The unique features of the HVS-ECA System for cooling tower applications are the electrolyte water softening process and the onsite water disinfection system integrated with a real-time water quality monitoring system for pH, TDS, ORP, free Chlorine, hardness and corrosion indicators. The HVS-ECA system continuously converts dissolved hardness ions (Calcium & Magnesium) from bulk water and extracts them physically as scale deposits out of the cooling water system, which enables cooling towers to operate at a much higher COC > 20, hence saving water by 10 to 20%. No industrial chemicals are needed as HVS-ECA systems generate oxidising agents onsite to mitigate bacteria growth

In addition, HVS is able to offer a total package of chemical-free water treatment systems for both the open loop (condenser cooling tower water) and close loop (evaporator cooling water) – to manage the water quality by utilising HVS-WQM system and the HVS-RBQ system (TBQ & TLD) – a proprietary rapid total bacterial detection and quantification system to monitor the bacterial trend over time.

Our Vision

To become a market leader in providing our clients with innovative, smart and technological solutions for the optimization of heat transfer equipment and maximising water-savings – consistently exceeding their expectations through lowering their operational costs and reducing environmental impact. We will continue to place a strong emphasis on developing innovative technology in tandem with industrial demand and to establish awareness, propagate, promote and encourage the use of energy-savings and energy-efficient products, as well as water-saving solutions that add value to our customers in the HVAC, oil & gas, marine & shipping and power & process industries.

Our Value

Our corporate culture and value have always been to empower our staff to take ownership and responsibility for their appointed roles and make sound decisions in the best interest of the company, nurturing sincere relationships and open communications to ensure continual success. We are committed to doing business in a consistent and transparent way with all our clients. We are committed to working with our clients to create the highest level of added value. We are committed to delivering excellence in service anytime and anywhere.

The Importance of Water Conservation and Water Quality Management

Water is an essential natural resource for human consumption. There are about 326 million trillion gallons of water on Earth. Less than 3% of the world’s water is freshwater, and more than two-thirds of that percentage is frozen in glaciers and ice caps. Even though it is a plentiful natural resource, only 0.04% of it may be utilised. The two main categories of freshwater sources are surface water sources, such as rivers, canals, waterfalls, dams, and reservoirs, and groundwater sources. In addition, due to waste generation and chemical leaks, industrial and agricultural operations are expanding quickly and have a substantial impact on environmental contaminants. It is important to ensure that water resources are safe and usable.

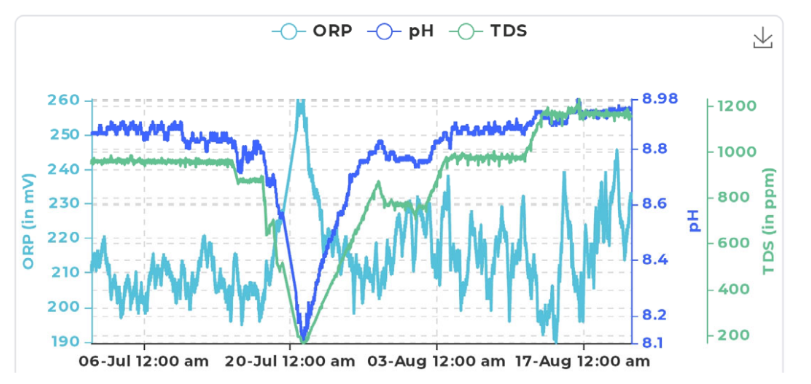

The world is experiencing issues with water demand and contamination as a result of growing globalisation. To prevent any quality issues brought on by water intake from diverse activities, water quality must be given close attention. Three categories can be made for water quality parameters. Physical properties such as conductivity, TDS, suspended solids, turbidity, salinity, temperature, smell, and colour are included in the first category. Chemical characteristics such as pH, ORP, corrosivity, dissolved oxygen, chemical oxygen demand (COD), biochemical oxygen demand (BOD), total organic carbon, heavy metal ions, and non-metallic toxins are included in the second group. All bacteria and pathogens fall within the microbiological section which is the third category. Water samples must be manually collected from various locations in order to be tested for quality, which is a tedious and time-consuming process.

Our HVS-WQM water monitoring system is designed as a cloud-based Internet of Things (IoT-based water quality monitoring) technology, which is a novel strategic network to connect various water parameter sensors of critical importance to track and monitor the trend in real-time of any specific application.

HVS‐WQM Water Quality Management System

The IoT currently significantly contributes to data monitoring, recording, storing, trending and displaying in addition to communication. IoT systems have opened up new possibilities and in recent years have seen an increase in the application of IoT technology to solve environmental problems such as air quality and water pollution. The HVS-WQM system uses IoT technology to enable real-time monitoring in order to streamline operations and regulate water quality more effectively.

The HVS-WQM system is designed primarily to augment the HVS-ECA chemical-free water treatment system for cooling tower water quality management. As such, the primary aim is to install sensors to measure water quality parameters like pH, TDS/conductivity, ORP, temperature, free chlorine, water hardness, corrosivity of copper, corrosivity of stainless steel and corrosivity of galvanised steel specifically configured for monitoring cooling tower water quality continuously on a real-time basis.

By tracking these various water quality indicators on a real-time continuous basis, the development of a sound and successful water quality management strategy could be further improved. With the use of digital data-gathering systems like the HVS-WQM system with features for detailed comparison between the various water quality parameters, including trend comparison and interpretation, one can get more insight into the relationship and interdependence of such operational parameters. Recognizing both short and long-term water quality patterns by way of data gathered over time will reveal insightful trends and may serve as early alerts for potential water quality issues. Monitoring specific water parameters like pH and TDS helps track the water quality and manage the discharge threshold as mandated by regulatory bodies. Regular water quality assessments and monitoring of corrosion indicators serve as early red flags of potential corrosivity in the water system. The key advantage is that the data on water quality from these different parameters is captured and displayed on the dashboard and is automatically uploaded to the cloud-based dashboard as real-time monitoring information for detailed analysis to proactively manage and prevent any potential water issues.

HVS‐ECA Chemical‐Free Water Treatment System with HVS‐WQM System to enable enhanced COC Operation

HVS Engineering has developed a proprietary pulsed technology for electro-chemical activation with the primary function of rapid de-scaling of the condenser tubes and electrolytically precipitating Calcium and Magnesium hardness ions from bulk water. It also has on-site disinfectant production to provide water sanitization and pH manipulation capability, which helps to reduce bio-growth and bacteria.

Utilising electro-chemical activation technology, the HVS-ECA system infuses circulating water (open loop & closed loop) with on-site generated powerful hypochlorites, strong oxidising agents and a slew of oxidants to replace the conventional harsh and toxic chemical usage in water treatment. Free chlorine is electrolytically generated and is not a harsh industrially manufactured chemical, which can be environmentally damaging both for the cooling tower system as well as when discharged into the sewage.

The HVS-ECA system is a novel dual-function electrochemical activation system that promotes the rapid removal of calcium, magnesium, carbonate and silicate scale-forming ions physically and generates a slew of mixed oxidants on-site during the process of electrochemical activation of water to replace the traditional standard chemicals and oxidising agents.

Operation of the HVS-ECA system also results in free chlorine production (with disinfection properties) onsite. The HVS-ECA system is principally for the purpose of removing scale-formation ions from the water within the cooling tower, thereby retarding as well as dissolving the existing scale deposits within the walls and pipes of the chiller system which enables a much more efficient chiller system, and lowers the energy consumption. Removal of scale formation ions enables the cooling tower to run at a higher cycle of concentration without frequent blowdown compared to existing industry practices thereby enabling more water savings in the range of 10% to 20%.

General Observation of Optimisation Period of HVS‐ECA System

During the initial start of HVS-ECA operation, i.e. the period commencing immediately after T&C (Optimisation Period) for retrofit projects, existing harden scale deposits, if any, adhering to the internal surfaces of the condenser water piping system may dissolve as part of the cleansing process, hence releasing encapsulated foreign particulates that will eventually be captured by the condenser pump strainer. Due to the release of scale-encapsulated contaminants, more organic sedimentation and suspended solids may be observed at the cold basins. The Condenser pump strainer may need to be cleared of debris more often if the condenser flow is observed to have reduced.

Depending on the operational characteristics of the cooling tower, the total volume of water in circulation, the makeup water usage, the COC (Cycle of Concentration) setting, the blowdown frequency, the ambient environments, and the weather conditions, it may take between 3 to 6 months for the condenser water system to reach a near ‘steady-state’ condition after the implementation of the HVS-ECA System.

Benefits of HVS‐WQM Water Monitoring System

- Real-Time monitoring and tracking of COC for enhanced water savings.

- Real-Time monitoring and tracking of pH and TDS to ensure compliance with discharge limits.

- Real-Time monitoring and tracking of water treatment efficacy via ORP and/or free Chlorine.

- Real-Time monitoring and tracking of the corrosivity of water via LPR corrosion

- Real-Time monitoring and tracking of the hardness of water via Total Hardness indicator

- Provide a tool for managing and preventing water contamination as part of environmental planning.

- Regular water quality assessments and monitoring serve as a source of information to proactively manage and prevent potential water quality issues.

- Recognizing both short- and long-term water quality patterns helps track the water quality and manage the discharge threshold as mandated by regulatory bodies.

- Compliance with prevailing standards on acceptable water quality to combat water contamination and becoming more aware of the significance of efficient water quality monitoring metrics and techniques.

- Real-time water quality monitoring provides a useful tool to elicit a quick response to proactively manage and understand pollution levels affecting water quality.

Challenges of Cooling Towers to Operate at High COC

Cooling towers are routinely used in industry for removing waste heat from buildings, data centres, shopping malls, hospitals, hotels and process applications. These include comfort cooling, temperature and humidity control and process cooling. From the mechanical engineer’s perspective, the purpose of a cooling tower is to reject waste heat to the atmosphere by evaporative and sensible heat transfer without consideration of water conservation.

Cooling towers use a lot of water during the heat removal process. As much as 50% to 60% of water is consumed by cooling tower operations in a typical building. On this basis, cooling tower operations present a great opportunity for big water savings if one can manage the water quality with a controlled and progressive increase in the Cycle of Concentration (COC) to ascertain the tipping point of non‐acceptability of the physical conditions of the cooling tower, the water quality to meet discharge requirements and the threshold of bacteria in the cold basins.

From the perspective of water conservation, the operation of a cooling tower is best measured in terms of how efficiently it reduces freshwater consumption (i.e. minimised make-up water usage) and wastewater discharge (i.e. reduced bleed loss) and not just by how efficiently it rejects heat, although that is an important consideration and should not be ignored. Most towers are not designed to operate in such a manner as to maximise cycles of concentration (COC) and minimise water losses. As with most cooling tower operators, the main consideration is to design and operate the cooling tower to reject waste heat to the atmosphere by evaporative and sensible heat transfer at optimal operational efficiency without consideration of water conservation.

Due to the different approaches to water treatment in the market as well as the diversity and complexity of environmental conditions, most cooling tower operations adopt an “overly conservative approach to tower bleed frequency, i.e operate at low COC” even though it is well-understood that cooling tower water savings can be attained by increasing the cycles of concentration (COC).

These competing objectives of optimal heat transfer and maximum water savings present a tight balancing act between operating at the highest possible COC and yet maintaining acceptable cooling tower physical conditions such as suspended solids and dirt at cold basins, algae growth at infills and cold/hot water basins, scale deposition at infills as well as acceptable water quality such as TDS and pH thresholds to meet discharge requirements and meet the bacteria threshold mandated by government bodies. How this is best achieved requires a practical understanding of the various water quality, operating environmental conditions and treatment technology options.

A fundamental measure of cooling tower water savings efficiency is cycles of concentration (also known as concentration ratio). Cycles of concentration (COC) are defined by the ratio of the dissolved solids in the tower water to the dissolved solids in the makeup. This is easily and commonly determined by taking the specific conductivity of the cooling water and dividing it by the conductivity of the makeup.

An alternate, equally accurate method of calculating cycles of concentration is to take the makeup volume and divide it by the bleed volume. This is easily done if the tower is equipped with water metres on the makeup and bleed lines, a practice that is highly recommended. Defining COC is easy. Determining the optimum COC that yields maximum water efficiency without producing energy-robbing scale deposits in the heat transfer areas of the process is more difficult.